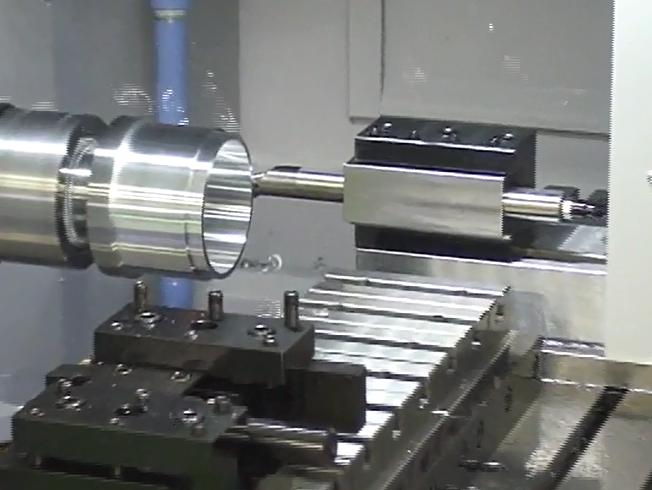

From bar to shaft. Changing in the shaft turning.

| Item | Description | |||

| Capacity | Workpiece diameter | Max. | mm | φ25 |

| Min. | φ5 | |||

| Workpiece lingth | Max. | 300 | ||

| Min. | 220 | |||

| Spindle | Command | (Step-less S4 digits direct command) | ||

| Speed | min-1 | Max.8,000 | ||

| Slide | Trsvel | mm | X axis:80 | |

| Y axis:150 | ||||

| Z axis:150 | ||||

| Rapid traverse | mm/min | X axis:8 | ||

| Y axis:10 | ||||

| Z axis:15 | ||||

| Jog feed rate | mm/min | 0~1,260 | ||

| Tool Tool size |

mm | 12 | ||

| Number of tools | >Each slide:Max 5 tools | |||

| Number of slide | 2 | |||

| Type pf tooling | Gang turret,tool fixed(Horizontal and vertical type) | |||

| Motor | Spindle | 2.2(FANUC αB112SS/2000i) | ||

| Slide | X axis | kw | 1 | |

| Y axis | 1 | |||

| Z axis | 2.7 | |||

| Power electricity | kva | 14(8kw) | ||

| Center height |

mm/min | 911 | ||

| Machine height | mm/min | 1.870 | ||

| Floor space | mm/min | 1,730(W)×1,240(L) | ||

| NC contril unit | kg | FANUC 0i-TF | ||

VARIOUS UNIT GROUPS

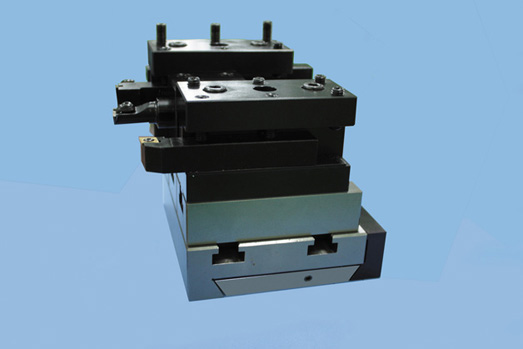

ABC TOOLING

Tool changes per plate

DRILLING UNIT

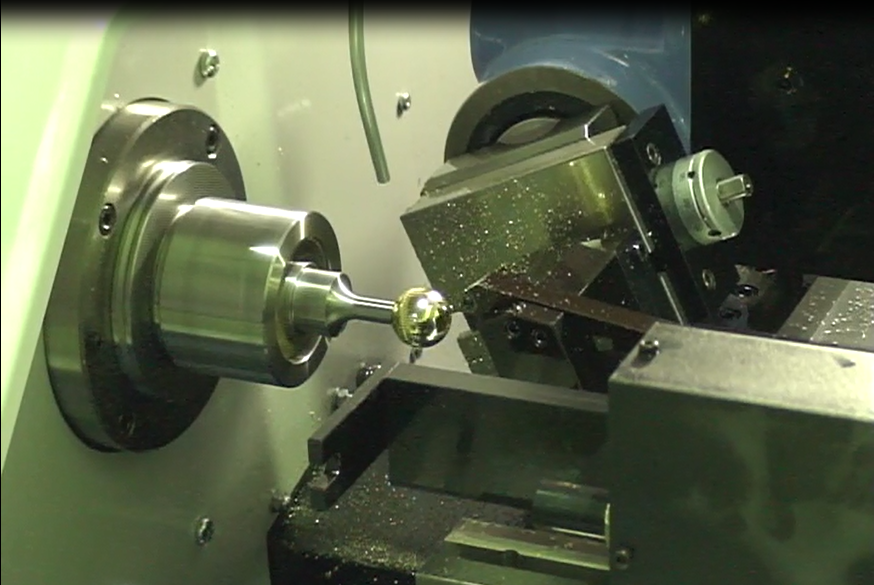

RADIUS TURNING

PTC CHIP CUTTING

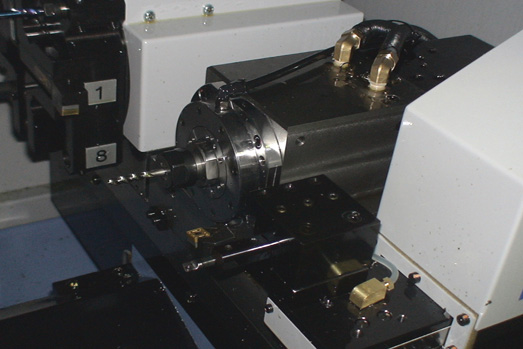

SUB SPINDLE

.jpg)

TAP UNIT 2 AXIS

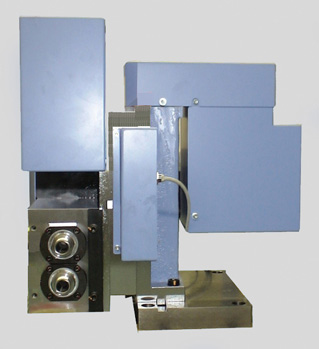

ROBOT STATION

.jpg)